Custom Wound Armatures

High Performance racing armatures hand-wound and carefully finished to exacting specifications.

All armatures feature the best high-temperature wire, diamond-trued comms, accurately ground stacks,

precision drill blank ball-bearing sized shafts and now dynamic balancing..

Available for all H.O. cars, G/Viper winds, Ghost Cat/Fusion winds and Tyco winds (for Slottech and Wizzard cars). Wire sizes from 31 - 40.

Pancake arms for AFX cars and Super II available as well.

Recommned wire sizes:

31 - Drag Racing

33 - 33.5 Unlimited cars 33 - 34 Neo Modified cars

34.5 Level 25 cars 35 - 36.5 Polymer Modified cars

37 - 38 Ceramic Modified cars 39 - 40 Gravity Cars

*NEW* K thin-lam blank - specially designed for today's cars

33 4 ' - 'G' / Viper $50.00

36/6 (double 36) 4' - Slottech / Tyco $55.00

35 7 1/2' Slottech / Tyco $50.00

35.5 6 1/2' 'G' / Viper $50.00

35.5 7 1/2' Fusion / Ghost Cat $50.00

35.5 8' 'G' / Viper $50.00

* SALE * some unclaimed arms - time to move them out.

33 4' Wizzard / Tyco $25.00

36/6 4' - Wizzard / Tyco $25.00

36 7' - Wizzard / Tyco $25.00

36 short stack 8' - Wizzard / Tyco $20.00

36.5 8 1/2' 'G' / Viper $20.00

Super Stock arms

Low ohm (5.9 - 6.2) HOPRA legal Super Stock arms for all chassis.

They come in standard and advanced timimng versions.

The advanced arms have shifted lams to allow for more advance without stressing the wires when just twisting the comm.

All of the Suoer Stock arms come with the wsrapped comm wires, epoxied,

trued comm and dynamically advanced.

$20.00 each (please let us know if you want the advanced version).

Order now as these tend to sell quickly.

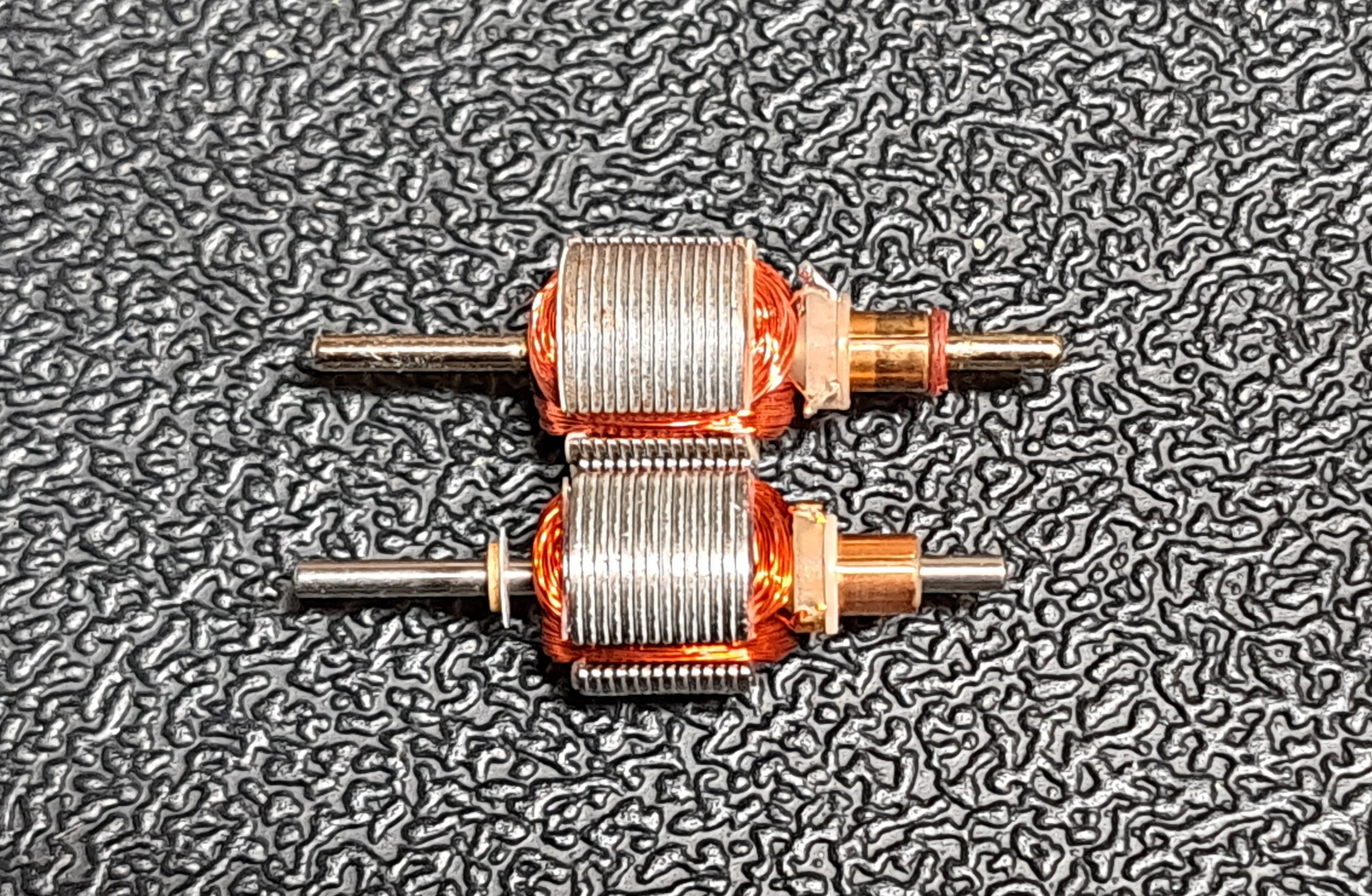

A note about the new Ghost Cat/Fusion armatures: While the timing on them is the same as the standard Tyco delta

wind timing (the space between the comm plates is in the center of the poles laminations, Viper/BSRT arms are different), the overall

length (spacing) of the armature is not the same. On the Ghost Cat/Fusion arm, the commutator is pushed back closer to the laminations,

so the front of the armature is closer to the brushes and the rear is further away from the bearing. Please see the photo to notice this difference.

A standard Tyco arm will fit in the Ghost Cat/Fusion, but the spacing will be improper for correct performance.

Standard Tyco on top, Ghost Cat/Fusion arm on bottom for comparison

Please Note: As stated in the instructions, any armature can be made to fail. Break in the

brushes at the lowest voltage to just get the motor spinning over freely. I only use 2 - 4 volts,

and never exceed 6 volts without a load on the car. Take your time, there is no quick way

to break in a motor. Free revving the arm may sound nice, but

that puts the kind of stresses on it that it will not normally experience when racing.

When ordering arms, please specify what chassis they are to be used in as they all fit somewhat differently

and we can custom fit them to that chassis. Making custom arms has many steps and processes

to arrive at the final product, so this is something that takes time and can not be done in a few days.